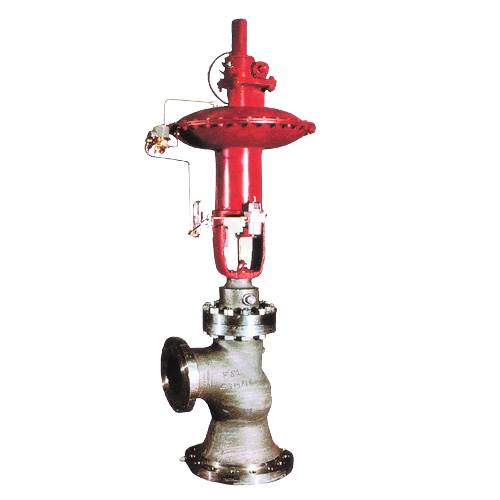

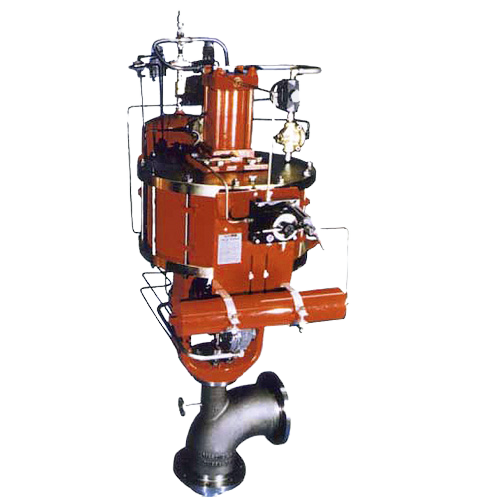

BHGE’s severe service valves are uniquely designed to operate reliably in tough environments. These valves are highly engineered and specifically designed for applications with large mass flow rates and high differential pressures.

Features & Benefits

Energy management trim solutions:

- Multiple heavy duty and valve technologies.

- Customized to meet your requirements.

- Reliable in extreme conditions.

Chemical

Chemical  Corrosive Service

Corrosive Service  Erosive Service

Erosive Service  Fugitive Emissions Control

Fugitive Emissions Control  General Service

General Service  Mining

Mining  Oil & Gas

Oil & Gas  Power Plant

Power Plant  Pulp & Paper

Pulp & Paper  Refinery

Refinery  Severe Service

Severe Service  Water / Wastewater

Water / Wastewater