Valves used in the chemical sector

84000 Series SteamForm™ Steam Conditioning Valve

The Masoneilan line of steam conditioning valves offers a wide range of features, including low noise trim and a patented water injection system, for applications that require both pressure and temperature reduction in an integrated package. The SteamForm* product line combines more than 125 years of pressure control expertise with the latest in desuperheating technology to offer a highly efficient steam conditioning solution.

Benefits of the 84000 Series SteamForm™ Steam Conditioning Valve include:

- ASME 816.34 based design with expanded outlet size to control steam velocity.

- Multi-stage pressure reduction trim controls steam pressure while reducing noise and vibration.

- Field serviceable trim design with compensation for thermal excursions in combined cycle applications.

- Class V shut-off performance reduces energy loss to downstream piping.

- High efficiency desuperheating via patented Flow Profiler to reduce downstream piping concerns.

- High performance spring loaded nozzles for fine atomization of injected spray water.

- Customizable design to match plant piping.

The Masoneilan 84000 SteamForm valve is a superior choice for steam conditioning applications requiring integrated pressure and temperature reduction such as:

- Turbine bypass systems.

- Process steam conditioning.

- Boiler extraction to process.

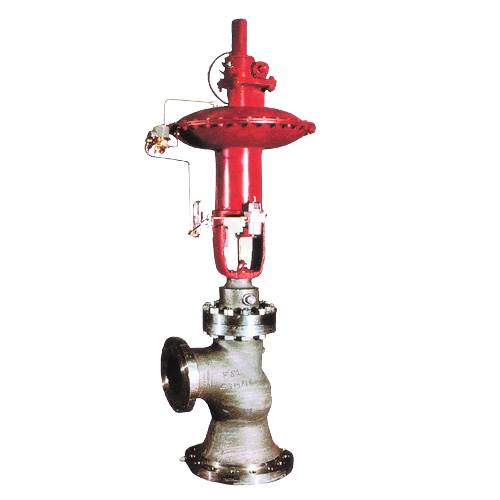

73000 Series Sweep Angle Valve

The 73000 Series control valve can throttle highly erosive, flashing, and two-phase flows.

Size

1” x 1” through 10” x 12” (25 x 25 mm through 250 x 300 mm)

Ratings & Connections

flanged: ANSI 150 – 2500

Body Materials

- carbon steel

- stainless steel

- titanium

- hastelloy

- others

Actuators

- Model 87/88 multi-spring diaphragm

- Model 51/52/53 piston cylinder

Trims:

- high capacity single stage

- reduced port venturi outlet

- ceramic and tungsten carbide optional

Inherent Characteristics

Linear

Specific applications:

- Mining

- Coal slurry

- Ash handling

- Hydrocarbon bottoms

71000 Series Visbreaker Valve

The 71000 Series is a modified sweep-angle valve that can reduce fluid impingement through the body.

This design includes heavy guiding and durable trim parts to withstand harsh operation.

Specific applications:

- Visbreaker

- Hot hydrocarbon fluid

- Coking applications

Size

2” x 3” through 10” x 12” (50 x 80 mm through 250 x 300 mm)

Ratings & Connections

flanged: ANSI 150 – 2500

Body Materials

carbon steel; stainless steel; chrome-moly

Actuators

model 87/88 multi-spring-opposed diaphragm; cylinder

Trim

heavy top plug guiding coupled with a threaded seat ring design to form an outlet venturi flow path for outlet area protection

Inherent Characteristics

linear

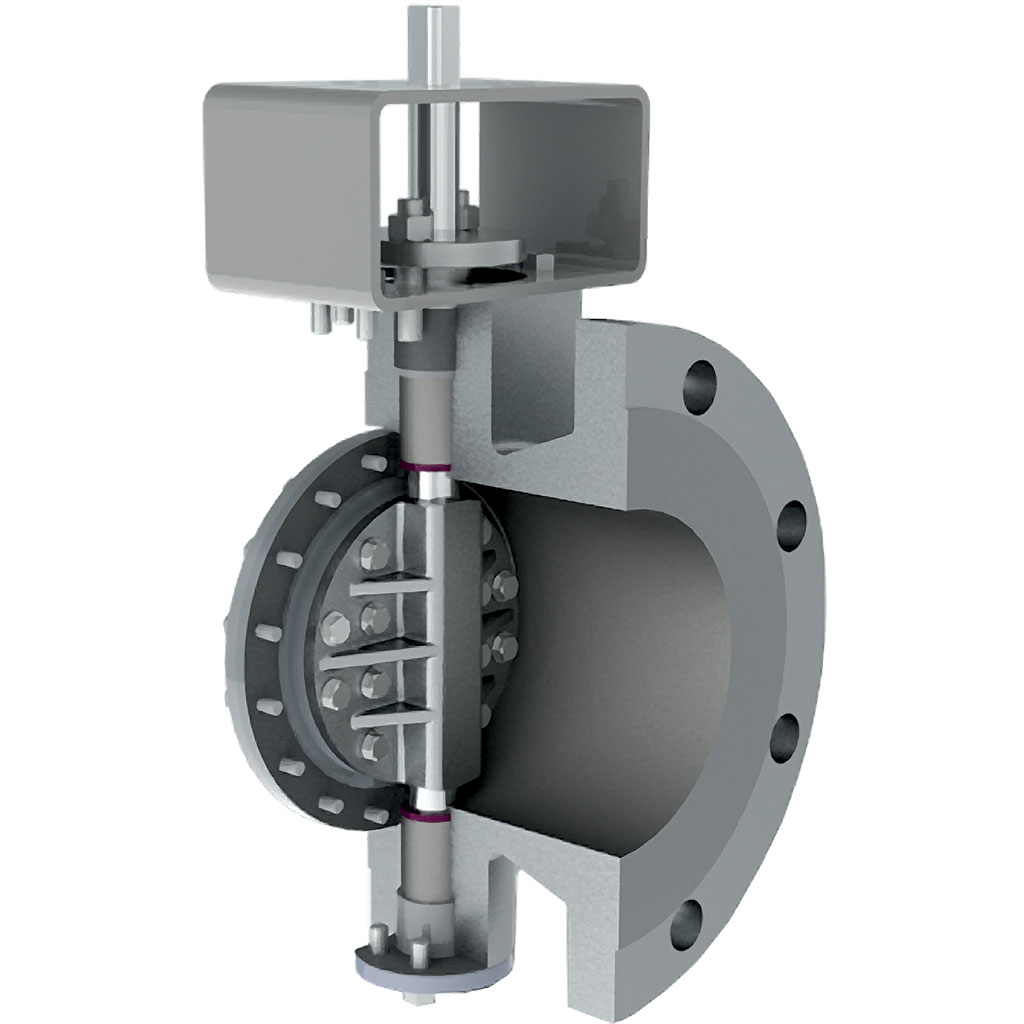

33000 Series Triple Offset Butterfly Valves

The 33000 Series Triple Offset Butterfly Valve incorporates new performance enhancing operational features, allowing for a more simplified manufacturing process. The result is exclusive patented range of superior performance zero leakage bi-directional triple offset butterfly valves, suitable for extreme pressure/temperature applications.

Sizes: 3” through 48”

(25 through 1200 mm)

Ratings and Connections:

• Wafer, Lugged, Double Flanged Short & Long Pattern

• ANSI 150 – 600

Body Materials:

• Carbon steel

• Stainless steel

• Duplex

Actuator:

• Model 31/32 spring diaphragm

• Model 33 spring diaphragm

Trim:

• Torqued butterfly

Inherent Characteristic:

• Equal percentage

39004 Series High Performance Butterfly Control Valves

The 39004 Series is a heavy-duty automatic throttling butterfly control valve with an eccentric disc for large flow rates and moderate-pressure applications.

Sizes: 3” through 48”

(80 through 1200 mm)

Ratings and Connections:

• Wafer and lug for mounting

between flanges: ANSI 150 – 600

Body Materials:

• Carbon steel

• Stainless steel

Actuators:

• Model 33 spring diaphragm

• Model 34 scotch yoke cylinder

• Model 96/97 pneumatic rack

and pinion

Trim:

• Double eccentric

Inherent Characteristic:

• Equal percentage

36005 Series V-Max™ Control Ball Valve

These high-capacity V-ported control ball valves offer automatic throttling capability with flexible shutoff options, simplified maintenance needs, and enhanced operational reliability.

The V-Max* rotary control valve offers high-capacity, heavy-duty automatic throttling capability.The valve’s advanced design features offer substantial benefits, including:

- Simplified alignment. The valve’s integrally cast raised face flanges (in compliance with ASME 150 or 300 Class standards) eliminate the need for long tie rods, significantly simplifying the alignment process.

- Installation flexibility. To meet a variety of application needs, the valve is available with two different face-to-face dimensions: standard construction complies with ISA S75.04 and IEC 534-3-2 standards and a short pattern complies with the ANSI B16.

- Enhanced flow capacities. A straight-through flow pattern provides exceptional capacities, while the patented dual-characterized V-port ball combines an equal percentage flow characteristic with highcapacities and greater than 500:1 rangeability.

- Excellent leakage control: A standard EF(emission free) seal packing system provides long-term, zero leakage† shaft sealing performance.

Sizes: 1” through 12”

(25 through 300 mm)

Ratings and Connections:

• Flanged: ANSI 150 – 300

Body Materials:

• Carbon steel

• Stainless steel

Actuators:

• Model 33 spring diaphragm

• Model 31/32 spring diaphragm

• Model 34 scotch yoke cylinder

Trim:

• Dual characterized, v-ported segmented ball

Inherent Characteristic:

• Equal percentage

35002 Series Camflex™ Rotary Control Valve

When the original Camflex was introduced in 1968 it created a revolutionary new category of control valves -the Rotary Globe. This new type of valve converged the best control features of a conventional globe valve with a rotary action to produce a valve capable of replacing at least 80% of the control valves in use at that time.

Many improvements and enhancements have been made since that time, with over 1 million Camflex valves installed in a wide range of process control applications. Everything from the most basic water applications up to severely erosive services that would tear other valves apart. The Masoneilan Camflex valve is designed first and foremost to be an excellent control valve and has proven to truly be a Universal Rotary Globe control valve.

Sizes: 1” through 16”

(25 through 400 mm)

Ratings and Connections:

• Flanged: ANSI 150 – 600

• Flangeless: ANSI 150 – 600

UNI-DIN 10 – 100

• Screwed: NPT (1” through 2”)

Body Materials:

• Carbon steel

• Stainless steel

• High nickel alloy

Actuators:

• Model 35 spring diaphragm

• 70 Series cylinder

Trim:

• Eccentric rotary plug

Inherent Characteristic:

• Linear

31000 Series Rotary Control Valve

The 31000 Series is a PFA-lined control valve with an eccentric rotary plug that offers tight shut-off, low dynamic forces, and control. This valve is suitable for hydrofluoric and sulfuric acid applications.

Sizes: 1” through 3”

(25 through 80 mm

Ratings and Connections:

• Flanged: ANSI 150

UNI-DIN 10 – 16

Body Materials:

• Cast iron PFA lined

Actuator:

• Model 35 spring-opposed rolling diaphragm

Trim:

• Eccentric rotary plug

Inherent Characteristic:

• Linear

BR200/BR400 High Capacity Volume Booster Relays

Model BR200 and BR400 pneumatic booster relays offer high capacity air volume boost for faster, dynamic control valve system response. These devices feature a 1:1 input-to-output ratio with a maximum supply and signal pressure of 150 psi.

The BR200 and BR400 also include an integrated internal bypass valve for sensitivity adjustment and dynamic response optimization. These devices also have integrated filters in both the supply and signal ports and are configured using stainless steel components and corrosion resistant finishes for a robust and reliable assembly.

Input/Output Ratio:

• 1:1

Maximum Supply/Signal Pressure:

• 150 psi

Temperature range:

• -30°C to +83°C, option for -50°C to

+60°C or 0°C to +100°C

Maximum Cv BR200:

• Supply: 1.2

• Exhaust: 1.2

Maximum Cv BR400:

• Supply: 2.6

• Exhaust: 2.4

Model 4411 Electro-Pneumatic Transducer

The 4411 I/P is manufactured with Reedex™ digital-micro valve technology for fast response. It is not sensitive to vibration.

• Low air consumption

• Adjustable tight shut-off feature

Output capacity:

• 12 scfm (20.4 Nm3/h)

Signals:

• Input: 4 – 20 mA (100 mA max)

• Output: 3 – 15 psig, 6 – 30 psig

Certification:

• Explosion proof and intrinsically safe enclosure rating per IP 66 and NEMA X

Chemical

Chemical  Corrosive Service

Corrosive Service  Erosive Service

Erosive Service  Fugitive Emissions Control

Fugitive Emissions Control  General Service

General Service  Mining

Mining  Oil & Gas

Oil & Gas  Power Plant

Power Plant  Pulp & Paper

Pulp & Paper  Refinery

Refinery  Severe Service

Severe Service  Water / Wastewater

Water / Wastewater